4. CHARCOAL BRIQUITTE PRESS SERIES

This series of charcoal briquette press machines

can be used to make charcoal briquettes of different shapes.

The raw material comes from small size waste charcoal broken

in storage or while transportation, or comes from charcoal

chunk after biomass burned. With this machine, the waste

charcoal chunk can be made into charcoal briquettes or charcoal

stick and recycled for barbecue, room heating etc.

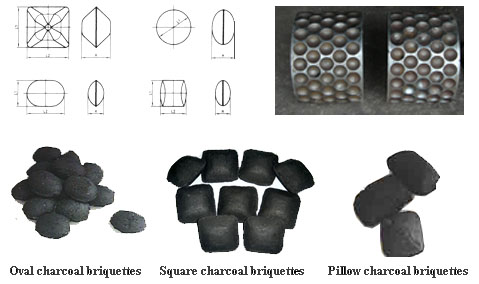

(1) Roll Type Charcoal Briquette Press Model 350

(For oval shape briquettes from charcoal powder)

Roll Type Charcoal Briquette Press Model 350

This machine can be used to make charcoal briquettes of

oval shape.

This machine also can be used to make briquettes from anthracite

powder, coal powder and many other materials.

Pressure of mould wheel: 600kg/cm2

Rotate speed of mould wheel: 16r/min

Associated power: 4kw-4

Yield (capacity): 2-3T/h (for charcoal) 5-6t/h (for coal)

Material of roller: 20 Mn

Weight: 600kg

Size: 3600 *1500 *1600 mm

(2) Four Rollers Double Pressing Briquette Press Model

360II

(For oval, square and pillow shape briquettes from charcoal

powder)

Four Rollers Double Pressing Briquette Press Model 360II

Four Rollers Double Pressing Briquette Press can supply

higher pressure and higher intensity during production of

briquettes; it’s mainly used in the briquettes making

of various color and black metallic mine powder. It can

be used to make briquettes from coal powder, charcoal powder

and coke powder with binder.

This type of briquette press have two larger rollers in

a fixed position in the frame, the other two smaller rollers

are moveable. As its named implied, it has four rollers

and press briquettes for twice times, so it make briquettes

stronger and in proper density. Meanwhile, it is easy for

combustion, no smell and last longer when burning.

This machine is national patent product in China.

Capacity: 4000KG/Hour (For coal powder)

2000KG/Hour (For charcoal powder)

Power: 7.5-11 KW

Width of roller: 250mm

Diameter of roller: 360mm

Pressure of machine: 20-30T

Endurable pressure of briquettes: 60kg

Rotation of main shaft: 18 rev/min

Material of roller: 65 Mn

Weight of machine: 1850KG

Size: 1300*1150*2050mm

This machine can be used to make charcoal briquettes of

oval, square and pillow shape (with different moulds) from

charcoal dust or charcoal powder.

Diameters of briquettes range from 20mm to 60mm according

to requirement of customers.

(3) Model YPC500 Briquette Press

This machine is applicable for makin g

briquettes of Round, Square, Rectangle and Cube shape from

charcoal powder. The output briquette is in perfect shape,

good appearance, and high quality and strong enough that

is not easy broken when dropped from from 150 cm height.

Meanwhile, it is easy for combustion, no smell and last

longer when burning. g

briquettes of Round, Square, Rectangle and Cube shape from

charcoal powder. The output briquette is in perfect shape,

good appearance, and high quality and strong enough that

is not easy broken when dropped from from 150 cm height.

Meanwhile, it is easy for combustion, no smell and last

longer when burning.

Output Capacity: 9000 pieces of briquettes per hour (for

briquettes of 10g)

Shape of products: Round, Square, Rectangle, Cube shape

Power: 7.5kw

Size: 1200×900×1500mm

Weight: 2500KG

Shelf life: 6 years

Term of Warranty: 12 Month

|